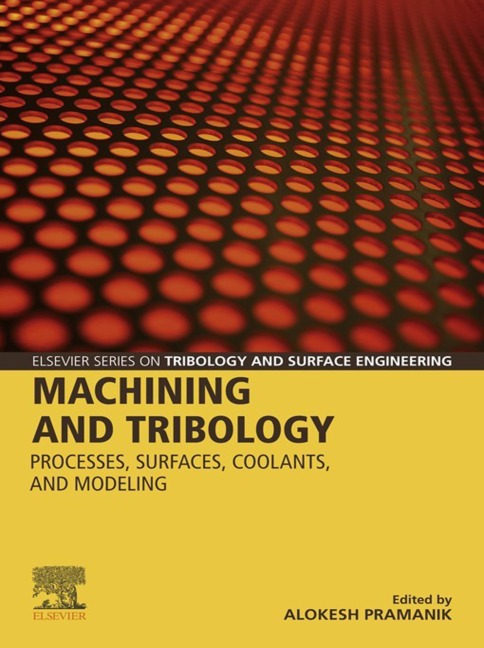

Beschreibung

Machining and Tribology provides insight into both the role of tribology in machining and the effects of various machining processes on tribology, exploring topics such as machining mechanisms, coolant technology, tool wear, and more. Covering the latest research, the book starts by looking at the tribological aspects of turning, milling, and drilling processes. From there, it explores the effects of different coolants such as flood, minimum quantity lubrication, and cryogenics on machining forces, tool wear, friction, chip formation, and surface generation during various machining processes. Tribological considerations of machined components follow, and the volume concludes with chapters covering simulation scenarios for predicting machining forces, tool wear, surface generation, and chip formation.- Draws upon the science of tribology to better understand, predict, and improve machining processes

- Covers tribology in different types of machining such as turning, milling, grinding, abrasive jet machining, and others

- Explores the underlying mechanisms of coolant contributions on machining processes

- Applies simulation techniques to explore the mechanism of nano-machining

Inhaltsverzeichnis

1. Introduction to machining tribologyMarta Bogdan-Chudy, Piotr Nieslony, and Grzegorz Królczyk2. The underlying mechanisms of coolant contribution in the machining processBikash Chandra Behera, Chetan, Sudarsan Ghosh, and P. Venkateswara Rao3. Advanced cooling-lubrication technologies in metal machiningMozammel Mia, Muhommad Azizur Rahman, Munish Kumar Gupta, Neeraj Sharma, Mohd Danish, and Chander Prakasj4. Abrasive wear during machining of hard nanostructured cermet coatingsA.K. Basak and Alokesh Pramanik5. Tribology in (abrasive) water jet machining: A reviewK. Bimla Mardi, A.R. Dixit, Alokesh Pramanik, and A.K. Basak6. Modeling and analysis of forces and finishing spot size in the ball end magnetorheological finishing (BEMRF) processZafar Alam, Faiz Iqbal, and Sunil Jha7. Simulation of force, energy, and surface integrity during nanometric machining by molecular dynamicsChenshuo Liu, Pei Chen, and Zhiwei Zhang8. Molecular dynamics simulation of friction, lubrication, and tool wear during nanometric machiningJia Li, Yuanyuan Tian, and Qihong Fang9. Tribological aspects of different machining processesGourhari Ghosh, Mayank Kumar, Ajay M. Sidpara, and P.P. Bandyopadhyay10. Surface texturing for improved tribological performance in deep hole drillingAkshay Chaudhari, Malarvizhi Sankaranarayanasamy, and A. Senthil Kumar

Technik

Sie können dieses eBook zum Beispiel mit den folgenden Geräten lesen:

• tolino Reader

Laden Sie das eBook direkt über den Reader-Shop auf dem tolino herunter oder übertragen Sie das eBook auf Ihren tolino mit einer kostenlosen Software wie beispielsweise Adobe Digital Editions.

• Sony Reader & andere eBook Reader

Laden Sie das eBook direkt über den Reader-Shop herunter oder übertragen Sie das eBook mit der kostenlosen Software Sony READER FOR PC/Mac oder Adobe Digital Editions auf ein Standard-Lesegeräte.

• Tablets & Smartphones

Möchten Sie dieses eBook auf Ihrem Smartphone oder Tablet lesen, finden Sie hier unsere kostenlose Lese-App für iPhone/iPad und Android Smartphone/Tablets.

• PC & Mac

Lesen Sie das eBook direkt nach dem Herunterladen mit einer kostenlosen Lesesoftware, beispielsweise Adobe Digital Editions, Sony READER FOR PC/Mac oder direkt über Ihre eBook-Bibliothek in Ihrem Konto unter „Meine eBooks“ - „Sofort online lesen über Meine Bibliothek“.

Bitte beachten Sie, dass die Kindle-Geräte das Format nicht unterstützen und dieses eBook somit nicht auf Kindle-Geräten lesbar ist.

Barrierefreiheit

Status der Barrierefreiheit

EPUB Accessibility 1.1

WCAG Version 2.1

WCAG Stufe AA

Alternativbeschreibungen

Kurze Alternativtexte

Vollständige Alternativtexte

Navigation

Inhaltsverzeichnis mit Links

Register mit Links

Steuerelemente

Einfache Navigation

Audio

Alle Inhalte über Text-to-Speech-Bildschirmlesegeräte oder ertastbare Lesegeräte (Brailleschrift) zugänglich

Lesbarkeit

Hoher Kontrast

Sehr hoher Kontrast

Hersteller

Und dann auf "Zum Home-Bildschirm [+]".

Und dann auf "Zum Home-Bildschirm [+]".