Beschreibung

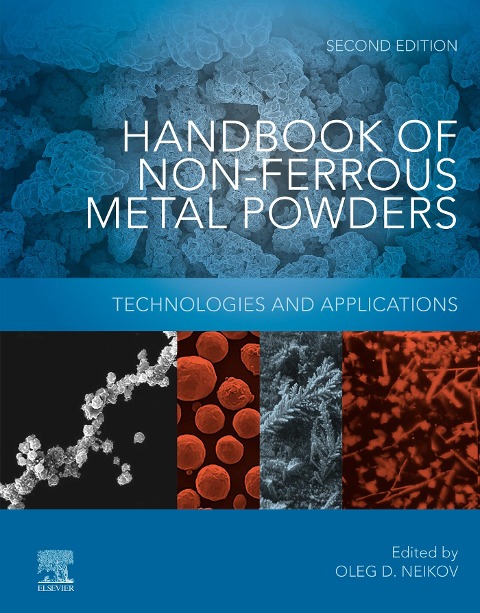

Handbook of Non-Ferrous Metal Powders: Technologies and Applications, Second Edition, provides information on the manufacture and use of powders of non-ferrous metals that has taken place for many years in the area previously known as Soviet Russia. It presents the huge amount of knowledge and experience that has built up over the last fifty years. Originally published in Russia by several prominent scientists, researchers and engineers, this presents an update to the first book that includes sections on classification, properties, treatment methods and production. This updated edition contains new content on the powders, along with newer methods of 3D printing.

- Covers the manufacturing methods, properties and importance of the following metals: aluminum, titanium, magnesium, copper, nickel, cobalt, zinc, cadmium, noble metals, rare earth metals, lead, tin and bismuth- Includes new content on recent advances, such as additive manufacturing and 3D printing of non-ferrous metal alloys and specific powders for advanced techniques, including metal injection molding technologies- Expands on topics such as safety engineering in the production of powders and advanced areas of engineering research, such as nanopowder processes

Portrait

Oleg Domianovich Neikov holds a doctorate in material science at the Institute for Problems in Materials Science of National Academy of Science of Ukraine (IPMS), Kiev, Ukraine. Since 1970, he has been worked at the IPMS where he was promoted from research assistant to the head of the department of metallic powder synthesis and processing. During 40 years, Neikov was a member of the editorial boards of Powder Metallurgy and Metal Ceramics Journal. Dr. Neikov is author of more than 350 scientific publications, more than 40 patented investigations, and 8 monographs, including 'Air suction and dedusting in production of powders. Moscow (Russia): Metallurgia; 1981, Handbook of non-ferrous metal powders. Moscow: Metallurgia; 1997 [in Russian], Handbook of non-ferrous metal powders. 1st ed. Elsevier; 2009. His professional main field is the powder metallurgy of reactive metals (powder obtaining and processing; phiysics of flammability and explosion of metal powders); the current research interests are the rapid solidification processes, melt atomization and surface chemistry and physics.Nikolay Aleksandrovich Yefimov holds the Ph.D. degree in Institute for Problems in Materials Science of National Academy of Science of Ukraine (IPMS), Kiev, Ukraine in 2000. Since 2015, he has been working as a leading researcher in IPMS. Nikolay Yefimov graduated from the Kiev Polytechnic Institute in 1992 with a specialization in "physics of metals". Nikolay Yefimov is author of more than 120 scientific publication, including monograph Quasicrystals and nano-quasicrystals are new promising materials. In: Promising materials, Vitebsk, Belarus, 2009.Naboychenko Stanislav Stepanovich is Corresponding Member of the Russian Academy of Sciences, Professor, and Doctor of Technical Sciences. Naboychenko S.S. is a member of the editorial boards of the leading Russian metallurgical journals "Non-Ferrous Metals", "Russian Journal of Non-Ferrous Metals". He is an expert in the field of hydrometallurgical processes; he devoted a large number of works to autoclave processes, the author of more than 450 scientific papers. Stanislav Stepanovich Naboichenko is a recognized scientist in the field of autoclave hydrometallurgy of non-ferrous metals, the author of a well known in Russia and abroad study dedicated to kinetics of dissolution of copper sulfides, non-ferrous alloys, hydrogen precipitation of copper, antimony, bismuth powders and the synthesis of a number of their compounds. He proposed a number of advanced technologies for processing copper-zinc concentrates and industrial products of copper secondary raw materials.

Inhaltsverzeichnis

Section 1. Powder Characterization and Testing1. Powder Characterization and TestingSection 2. Powder Production Methods2. Mechanical Crushing and Grinding3. Mechanical Alloying4. Atomization and Granulation5. Gas-phase Method6. Carbonyl Method7. Reduction Methods8. Electrochemical Methods9. Nanopowders10. Powders for Porous Powder Metallurgy Technology11. Powders for Composites12. Powders for Additive Manufacturing ProcessesSection 3. Processing of Powders13. Processing of Powders and Processing EquipmentSection 4. Production of Non-Ferrous Metal Powders 14. Production of Aluminum Powders15. Production of Aluminum Alloy Powders16. Production of Magnesium and Magnesium Alloy Powders17. Production of Titanium and Titanium Alloy Powders18. Production of Copper and Copper Alloy Powders19. Production of Zinc, Cadmium and Their Alloy Powder20. Production of Nickel and Nickel Alloy Powders21. Production of Cobalt and Cobalt Alloy Powders22. Production of Refractory Metal Powders23. Production of Rare Metal Powders24. Production of Noble Metal Powders25. Production of Lead, Tin, Bismuth, and Their Alloys PowdersSection 5. Safety Engineering in the Production of Powders26. Safety Engineering in the Production of Powders

Technik

Sie können dieses eBook zum Beispiel mit den folgenden Geräten lesen:

• tolino Reader

Laden Sie das eBook direkt über den Reader-Shop auf dem tolino herunter oder übertragen Sie das eBook auf Ihren tolino mit einer kostenlosen Software wie beispielsweise Adobe Digital Editions.

• Sony Reader & andere eBook Reader

Laden Sie das eBook direkt über den Reader-Shop herunter oder übertragen Sie das eBook mit der kostenlosen Software Sony READER FOR PC/Mac oder Adobe Digital Editions auf ein Standard-Lesegeräte.

• Tablets & Smartphones

Möchten Sie dieses eBook auf Ihrem Smartphone oder Tablet lesen, finden Sie hier unsere kostenlose Lese-App für iPhone/iPad und Android Smartphone/Tablets.

• PC & Mac

Lesen Sie das eBook direkt nach dem Herunterladen mit einer kostenlosen Lesesoftware, beispielsweise Adobe Digital Editions, Sony READER FOR PC/Mac oder direkt über Ihre eBook-Bibliothek in Ihrem Konto unter „Meine eBooks“ - „Sofort online lesen über Meine Bibliothek“.

Bitte beachten Sie, dass die Kindle-Geräte das Format nicht unterstützen und dieses eBook somit nicht auf Kindle-Geräten lesbar ist.

Barrierefreiheit

Navigation

Inhaltsverzeichnis mit Links

Register mit Links

Hersteller

Und dann auf "Zum Home-Bildschirm [+]".

Und dann auf "Zum Home-Bildschirm [+]".